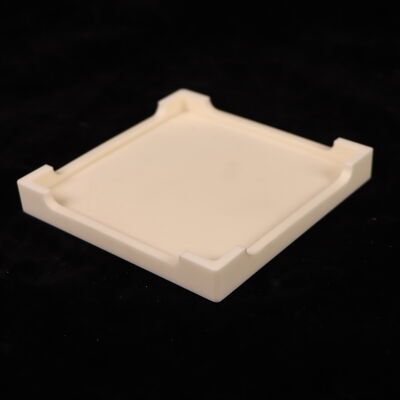

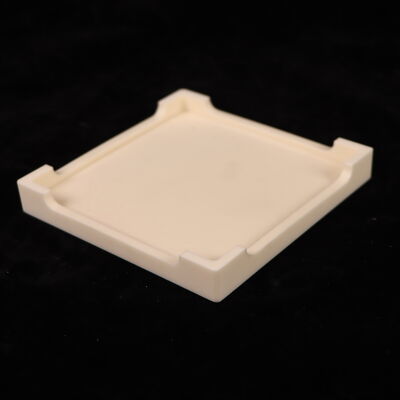

Product Description:

The Aluminum Oxide Ceramic product, commonly referred to as 99% Alumina ceramic plate, is a high-performance advanced ceramic material renowned for its exceptional mechanical and physical properties. This alumina ceramic substrate is widely utilized across various industries due to its outstanding combination of strength, hardness, and thermal stability. With its impressive characteristics, the alumina ceramic plate serves as an ideal solution for applications demanding durability, wear resistance, and electrical insulation.

One of the most notable attributes of this 99% Alumina ceramic plate is its remarkable Young's Modulus, ranging between 200 to 400 GPa. This high modulus of elasticity indicates the material's ability to resist deformation under stress, providing excellent rigidity and mechanical stability. Such a property is crucial in applications where dimensional stability under load is essential, such as in electronic substrates or structural components.

The density of this alumina ceramic substrate typically falls within 3.75 to 3.9 g/cm³. This relatively low density compared to metals makes the alumina ceramic plate a lightweight yet tough alternative for various engineering applications. Its lightweight nature contributes to easier handling and reduces the overall weight of assemblies where it is incorporated, without compromising strength or durability.

Hardness is another critical property of the alumina ceramic plate, boasting a value of 9 on the Mohs scale. This extreme hardness makes the 99% Alumina ceramic plate exceptionally resistant to scratches, abrasion, and wear. Consequently, it is frequently employed in environments where surface durability is paramount, such as in cutting tools, wear-resistant linings, and protective coatings. The hardness also ensures longevity and reduces maintenance costs over time.

With a Poisson's Ratio of approximately 0.25, this alumina ceramic substrate exhibits a balanced deformation behavior under mechanical stress. This ratio reflects the material's capability to undergo slight lateral expansion when compressed, contributing to its overall toughness and fracture resistance. Understanding this property is vital for engineers designing components that must withstand multidirectional forces without failure.

Perhaps one of the most impressive mechanical properties of the 99% Alumina ceramic plate is its compressive strength, which exceeds 3000 MPa. This extraordinarily high compressive strength allows the alumina ceramic plate to sustain substantial loads without fracturing, making it suitable for high-pressure environments and heavy-duty applications. Industries such as aerospace, automotive, and electronics often rely on this alumina ceramic substrate for components subjected to extreme compressive stresses.

In addition to its mechanical prowess, the alumina ceramic plate offers excellent thermal stability and electrical insulation properties. It can withstand high temperatures without deformation or loss of strength, which is beneficial in applications involving thermal cycling or exposure to harsh thermal environments. Moreover, the alumina ceramic substrate’s electrical insulating capabilities make it an ideal material for electronic components, substrates, and insulators where reliable electrical isolation is critical.

Overall, the 99% Alumina ceramic plate is a versatile and robust material that combines high Young's Modulus, optimal density, superior hardness, a balanced Poisson's Ratio, and exceptional compressive strength. Its unique properties make it indispensable in manufacturing durable, high-performance components across diverse sectors. Whether used as an alumina ceramic substrate in electronics, a wear-resistant alumina ceramic plate in industrial machinery, or a structural element in demanding engineering applications, this ceramic product consistently delivers reliability and longevity.

Choosing the 99% Alumina ceramic plate ensures enhanced performance, reduced wear and tear, and superior mechanical integrity, making it a smart investment for cutting-edge technological and industrial solutions.

Features:

- Product Name: Aluminum Oxide Ceramic

- Material: Alumina ceramic with 99% purity

- Poisson's Ratio: 0.25

- Flexural Strength: 200-400 MPa

- Dielectric Strength: 18-20 KV/mm

- Thermal Expansion: 8.9 x 10 -6 /K

- Available as 99% Alumina ceramic plate, suitable for various industrial applications

Technical Parameters:

| Hardness |

9 Mohs |

| Young's Modulus |

200-400 GPa |

| Compressive Strength |

>3000 MPa |

| Thermal Conductivity |

25-35 W/mK |

| Breakdown Voltage |

>20 KV |

| Thermal Expansion |

8.9 × 10 -6 /K |

| Flexural Strength |

200-400 MPa |

| Color |

White |

| Insulation Resistance |

>10 12 Ohm-cm |

| Dielectric Constant |

9.6 |

Applications:

The KAMTAI Aluminum Oxide Ceramic, model number KT-YHL, is an advanced alumina ceramic product originating from China and certified under ISO 9001 standards. This high-quality alumina ceramic plate is designed to meet the rigorous demands of various industrial applications where durability and thermal performance are critical. With a thermal conductivity range of 25-35 W/mK, this product excels in environments requiring efficient heat dissipation and thermal stability.

One of the most common application occasions for the KAMTAI alumina ceramic plate is in high temperature use scenarios. Its excellent tensile strength of 200-400 MPa and a density of 3.75-3.9g/cm³ make it ideal for components exposed to extreme heat and mechanical stress. Whether used in electronic substrates, heat exchangers, or insulating parts, this alumina ceramic ensures reliable performance without compromising structural integrity.

The product’s white color and a Poisson’s ratio of 0.25 further contribute to its versatility and resilience, allowing it to be used in precision machinery and high-performance equipment. Industries such as aerospace, automotive, electronics manufacturing, and chemical processing benefit from the robust features of the high temperature use alumina ceramic plate. Its resistance to wear, corrosion, and thermal shock makes it a preferred choice for protective coatings, cutting tools, and thermal insulation components.

KAMTAI offers this alumina ceramic plate with a minimum order quantity of 300PCS, packaged securely in wooden boxes to ensure safe delivery. The supply ability is substantial, reaching up to 500,000PCS per month, with a delivery lead time of 30 days after payment. Payment terms are based on TT, and the price is negotiable, accommodating various business needs and order volumes.

In summary, the KAMTAI KT-YHL alumina ceramic plate is a high-performance solution for industries requiring reliable, high temperature use alumina ceramic materials. Its superior mechanical and thermal properties make it an indispensable component for advanced manufacturing and industrial applications, ensuring longevity and efficiency in demanding environments.

Customization:

KAMTAI offers customized Aluminum Oxide Ceramic products under model number KT-YHL, proudly made in CHINA with ISO 9001 certification. Our alumina ceramic plates are designed for high temperature use, providing excellent dielectric constant of 9.6 and dielectric strength ranging from 18 to 20 KV/mm, ensuring superior performance in demanding environments.

We supply alumina ceramic plates with outstanding mechanical properties including flexural strength and tensile strength between 200-400 MPa, as well as thermal conductivity of 25-35 W/mK, making them ideal for various industrial applications.

Minimum order quantity is 300PCS, with competitive pricing available upon negotiation. All products are securely packaged in wooden boxes to ensure safe delivery. Delivery time is 30 days after payment with TT payment terms accepted.

Our supply ability reaches up to 500,000 PCS per month, ensuring reliable and timely fulfillment of your orders. Trust KAMTAI for high quality alumina ceramic plates tailored to your specific needs for high temperature use alumina ceramic plates and other applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!