Product Description:

The Kiln Posts are an essential component designed specifically for high-temperature industrial applications, offering exceptional durability and performance. Manufactured with a high-quality silicon carbide composition, these posts exhibit a density of 2.8g/cm3, ensuring robust mechanical strength and long-lasting stability even under extreme conditions.

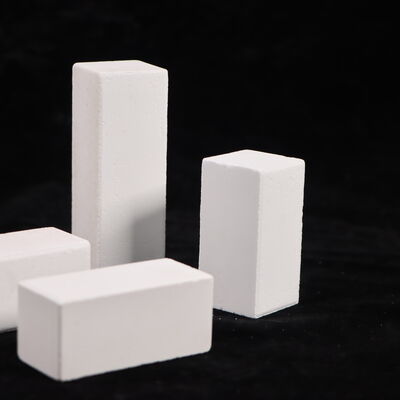

One of the standout features of these Kiln Posts is their superior purity level, with a silicon carbide (SIC) content exceeding 90%. This high SIC concentration not only enhances the thermal resistance but also improves the posts' chemical inertness, making them ideal for use in harsh kiln environments where other materials may degrade quickly. The white color of the Kiln Posts reflects their purity and quality, providing a clean and professional appearance that meets industrial standards.

Shaped in the form of bricks, these silicon carbide columns are engineered to provide optimal support and spacing within kilns and furnaces. The brick shape ensures easy stacking and placement, facilitating efficient heat distribution and structural integrity. Whether used as SIC props or SIC posts, they play a critical role in maintaining the integrity of ceramic, glass, and other high-temperature processes by holding workpieces securely in place.

With a maximum operating temperature of up to 1550℃, these Kiln Posts are perfectly suited for demanding applications such as firing ceramics, heat treatment of metals, and other thermal processes requiring stable and reliable support at elevated temperatures. The posts resist thermal shock and maintain their shape and strength during rapid temperature changes, which is crucial for maintaining consistent production quality.

The silicon carbide column design of these posts offers excellent thermal conductivity, helping to evenly distribute heat within the kiln and prevent localized overheating. This feature not only prolongs the life of the kiln furniture but also contributes to energy efficiency and improved process consistency. The combination of high density, purity, and heat resistance makes these SIC props indispensable for professionals seeking reliable kiln components.

In addition to their technical advantages, these SIC posts are also praised for their ease of use and compatibility with a wide range of kiln sizes and configurations. Their standardized brick shape allows for versatile application, whether used individually or in combination to create customized support structures. This flexibility makes them a preferred choice for ceramic artists, glass manufacturers, and industrial heat treatment facilities alike.

Overall, the Kiln Posts made from silicon carbide represent a high-performance solution that meets the rigorous demands of modern high-temperature processing. Their combination of density, purity, color, shape, and temperature tolerance ensures that they deliver consistent, reliable performance in even the most challenging environments. Whether you need a silicon carbide column, SIC prop, or SIC post, these kiln posts provide the strength and durability needed to support your kiln operations efficiently.

Features:

- Product Name: Kiln Posts

- Material: Corundum Mullite

- High corrosion resistance for extended durability

- Apparent porosity: 7-8%

- SIC content: >90%

- Shape: Brick

- Excellent sic prop for stable performance

- Durable sic post suitable for high-temperature applications

- Optimized sic prop to enhance thermal stability

Technical Parameters:

| Product Name |

Kiln Posts |

| Material |

Corundum Mullite |

| SIC Content (sic prop) |

>90% |

| Loading Softening Temperature |

>1750°C |

| Surface Treatment |

Unglazed |

| Corrosion Resistance |

High |

| Color |

White |

| High Temperature Crushing Strength |

>35MPa |

| Cold Crushing Strength |

>90MPa |

| Density |

2.8g/cm³ |

Applications:

The KAMTAI Kiln Posts, model KT-THGZZ, are high-quality corundum mullite bricks designed specifically for industrial kiln applications. Manufactured in China under strict ISO 9001 certification, these kiln posts offer excellent corrosion resistance and can withstand loading softening temperatures above 1750°C, making them ideal for use in high-temperature environments. Their unglazed surface treatment ensures durability and longevity even under extreme thermal stress.

These sic posts are widely used in various ceramic and glass kiln operations where reliable support and heat resistance are critical. The unglazed brick shape allows for stable stacking and positioning within kiln chambers, ensuring optimal heat distribution and product protection during firing processes. Due to their robust corrosion resistance, these sic posts are particularly suited for applications involving corrosive atmospheres or repeated thermal cycles.

The KAMTAI KT-THGZZ kiln posts are packaged securely in wooden boxes to prevent damage during transportation. With a supply ability of up to 500,000 pieces per month and a standard delivery time of 30 days after payment, they cater efficiently to large-scale manufacturing needs. The minimum order quantity is 1000 pieces, and pricing is negotiable to accommodate different client requirements. Payment terms are TT, ensuring smooth and reliable transactions.

In addition to their use as sic posts, these kiln bricks also function effectively as sic props, providing essential support for ceramic ware and glass during firing. Their high mechanical strength and resistance to high temperatures make them indispensable in industries such as porcelain manufacturing, glass production, and refractory lining installations. Their versatility and performance make them a preferred choice for engineers and kiln operators aiming for superior product quality and process efficiency.

Overall, the KAMTAI KT-THGZZ kiln posts combine advanced material technology with practical design to deliver outstanding performance in demanding kiln environments. Whether used as sic posts or sic props, they ensure structural integrity and longevity, contributing significantly to improved firing outcomes and operational reliability.

Customization:

Introducing the KAMTAI Kiln Posts, model number KT-THGZZ, proudly made in CHINA and certified with ISO 9001. These silicon carbide columns are designed to offer exceptional high temperature resistance, making them ideal for various industrial kiln applications.

Crafted from premium Corundum Mullite material with a high SIC content of over 90%, our silicon carbide columns exhibit superior corrosion resistance and durability. The unglazed surface treatment ensures optimal performance under extreme conditions, maintaining structural integrity and longevity.

Available in a pristine white color, each kiln post is carefully packaged in a sturdy wooden box to guarantee safe delivery. We offer a minimum order quantity of 1000PCS, with a supply ability of up to 500,000PCS per month.

Our delivery time is 30 days after payment, with payment terms based on TT. Pricing is negotiable to meet your specific needs. Trust KAMTAI for high-quality, reliable silicon carbide columns that provide outstanding high temperature resistance and corrosion protection.

Support and Services:

Our Kiln Posts are designed to provide reliable support and stability for your kiln shelves during high-temperature firings. Manufactured from high-quality refractory materials, these posts can withstand extreme heat without cracking or warping, ensuring consistent kiln performance.

For optimal use, place the kiln posts evenly to distribute the weight of the kiln shelves and wares. This helps prevent damage to both the kiln furniture and your ceramic pieces. Regularly inspect the posts for signs of wear or damage, and replace them as needed to maintain kiln safety and efficiency.

We offer technical support to assist with installation guidance, troubleshooting, and recommendations for kiln shelf configurations. Our team is dedicated to helping you maximize the lifespan and functionality of your kiln posts to achieve the best firing results.

In addition to technical support, we provide services including custom sizing and shaping of kiln posts to fit specialized kiln designs. Whether you require standard sizes or custom solutions, our expertise ensures you receive the right product for your specific firing needs.

Proper handling and storage of kiln posts are essential to prevent damage before use. Store them in a dry, stable environment away from moisture and impacts. When transporting, handle with care to avoid chipping or breaking.

By choosing our kiln posts, you invest in durable, high-performance kiln furniture supported by comprehensive technical assistance and service options tailored to your ceramic firing applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!