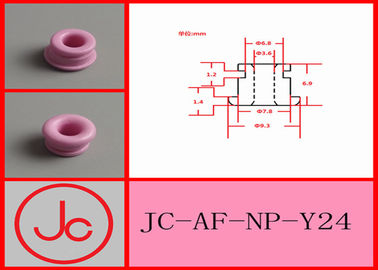

Industrial High Quality AL2O3 alumina ceramic textile eyelets wire guide

1. Features:

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) High strength

6) Used in all electric products, electric heating products and wear resistant machinery parts.

7) OEM, ODM and OBM are welcomed

Textile ceramic eyelets for industrial

Alumina ceramic is kind of structural ceramics, with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, devices porcelain, spark plugs and other products. We can make the part by hot injection pressing, dry pressing, 200T isostatic pressing and extrusion productive technology etc.

Our service:

l Technical personnel: We are equipped with professional technical personnel

l Stock:Large quantity in stock ensured fast delivery.

l Inquiry response: Your inquiries will be replied in 24 hours.

l Delivery time: Your shipment will be loaded in 15~25days.depends on quantity.

l Payment term: T/T, L/C, D/P, D/A, Western Union (Sample only)

l Customized:We can supply the products according to customer's drawings, samples and performance requirement.

2.Textile ceramic eyelets for industrial

| Performance For Industrial Ceramic |

|

| Item |

|

Unit |

95 Al2O3 |

96 Al2O3 |

99 Al2O3 |

|

| Physical Characteristics |

Heat resistance |

0C |

1500 |

1550 |

1800 |

|

| Bulk density |

g/cm3 |

3.6 |

3.6 |

3.9 |

|

| Water absorption |

% |

0 |

0 |

0 |

|

Mechanical Characteristics |

Flexural strength |

Mpa |

320 |

340 |

360 |

|

| Hardness vickers |

Gpa |

12.2 |

13.5 |

15.6 |

|

| Elastic modulus |

Gpa |

280 |

320 |

370 |

|

| Poisson’s ratio |

|

0.22 |

0.23 |

0.23 |

|

| Thermal Characteristics |

Linear expansion coefficient |

(20-5000C) 10-6/0C |

7.1 |

7.2 |

8 |

|

| Thermal conductivity |

w/(m.k) |

16 |

24 |

32 |

|

| Specific Heat |

*10-3J/(kg*K) |

0.78 |

0.78 |

0.9 |

|

| Electrical Characteristics |

Dielectric constant (1MHZ) |

- |

9 |

9.4 |

9.9 |

|

| Dielectric loss angle |

*10-4 |

15 |

5 |

1 |

|

| Dielectric strength |

*106V/m |

12 |

15 |

15 |

|

| Processing technology |

|

| Process range (mm) |

|

| Outside Diameter |

1---300 |

|

| Inside Diameter |

0.5---300 |

|

| Length |

0.5---600 |

|

| Accuracy of working (mm) |

|

| Perpendicularity |

0.001 |

|

| Concentricity |

0.001 |

|

| Roundness |

0.0005 |

|

| Straightness |

0.005 |

|

| Parallelism |

0.01 |

|

| Planeness |

0.005 |

|

| Roughness |

0.005 |

|

| Fit clearance |

0.005 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!